NINA-B40 series (open CPU)

Stand-alone Bluetooth 5.1 low energy modules

Warehouse automation can be an asset in fast-moving environments where thousands, if not millions, of individual supply chains intersect. This happens at cargo terminals, logistics hubs, and vendor warehouses, making them some of the most logistically challenging environments.

Monitoring the location of palettes, roll cages, or Kanban containers containing goods and leveraging the benefits of automation systems is essential to efficiently fulfill orders, plan capacity, and address bottlenecks as they arise.

Automation warehouse systems can provide air and sea cargo terminals with precise operational support for secure asset delivery. These environments benefit from seamless indoor/outdoor positioning solutions, such as combining GPS with Bluetooth mesh and direction finding.

Automation manufacturers can maximize coverage of pallets, IBCs, and roll cages, widely used in logistics for efficient warehouse goods handling. To achieve this, they can equip them with trackers that require redundant positioning technologies such as a combination of GPS, Wi-Fi sniffing, and Bluetooth direction finding.

Kanban containers, standard in intralogistics for loose items like screws, nuts, and bolts, use Radio Frequency Identification (RFID) for warehouse automation. Replacing these with Bluetooth low-energy tags simplifies infrastructure for inbound/outbound raw material monitoring systems and improves global scalability.

Stand-alone Bluetooth 5.1 low energy modules

Stand-alone Bluetooth 5.2 low energy modules

u-blox M10 standard precision GNSS modules

u-blox M9 standard precision GNSS module

Stand-alone Bluetooth 5.2 low energy modules

u-blox F9 high precision GNSS module

GNSS correction service

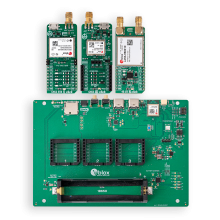

High precision GNSS explorer kit

High precision GNSS explorer kit

Connect with one of our experts to learn more about our product range today.