Case studies

u-blox 智能声学技术助力风力发电创新

监测软件公司 Ping Monitor 和物联网遥测技术公司 Lattech Systems 携手 u-blox,将声学传感器的数据连接至云端,以持续监控风力涡轮机叶片的性能状况,成为改变清洁能源格局的创新者。

It’s hard to communicate data between IoT devices and the enterprise

On the surface, it seems simple. There are some IoT sensor devices, some important data, a network, and a cloud platform that receives the data. But after taking a closer look, it’s not quite so simple after all. There are questions to be answered and complexities to be solved before launching any IoT project. What connectivity? Which network? How to scale? Is it secure? What about power consumption and data efficiency? What’s the interface to get my data to the enterprise? What will all this cost? Finding the answers becomes crucial to the project's success.

Ping Monitor and Lattech Systems partnered with u-blox to connect acoustic sensor data to the cloud for continuous monitoring of wind turbine blade health. Working together, the device to enterprise challenge is solved through a scalable end-to-end IoT communication solution based on the MQTT message protocol. In the process of solving the complexity, the design also revolutionizes the way wind farms are maintained, bringing the industry forward to the age of IoT.

Wind turbines offer cleaner energy that is essential to addressing climate change1

Harnessing the wind’s energy by using wind turbines to generate electricity is a popular and sustainable energy source that is much cleaner for the environment than the burning of fossil fuels. In 2021, wind supplied over 6% of world electricity. To help meet the Paris Agreement goals to limit climate change, analysts say that wind energy should expand by over 1% of electricity generation per year.

Understanding the health of wind turbine blades and detecting defects before they become significant is critically important

Blade damage can occur due to erosion of either the tip or its leading-edge, lightning strikes, or by a weakening of structural integrity. Early damage detection allows prompt repair when the damage is smaller and cheaper to fix.

Until recently, traditional monitoring of wind turbine blade health involved a once or twice per year human or drone inspection. Interestingly, site technicians can ‘hear damage’, meaning that by experience, they are able to audibly detect when something is wrong.

If a site technician can hear damage, then so can a smart monitoring IoT device

That human detection can be replicated with a permanent reliable installation. The innovation is answered by the acoustic experts at Ping, who have introduced the world’s first smart IoT device that uses sound to monitor wind turbines to detect damage early and improve performance via continuous monitoring in the cloud.

Matthew Stead, co-founder and CEO remarked, ‘’Ping analyzes the sound from wind turbine blades to detect damage. The acoustic signature from a damaged blade is clearly different from a blade with no damage. It’s an innovative way to reduce risk for our customers because early detection reduces repair costs and avoids even costlier replacements.”

It needs to be extremely easy to get the data from IoT device to the cloud

While Ping’s expertise is in listening for acoustic anomalies, they needed a design partner with proficiency in connecting sensors and equipment to the cloud via cellular networks and were introduced to u-blox Design Partner Lattech Systems.

Truhann van der Poel, founder of Lattech Systems added, ‘Our goal for this design was to make the complexity invisible to the customer. It needed simple connectivity, something that could work globally, with no setup, and that a customer could easily install. But the key differentiator was that we needed to solve the challenge of getting the data from the device to the cloud management platform, and that is where u-blox Thingstream came into play.’

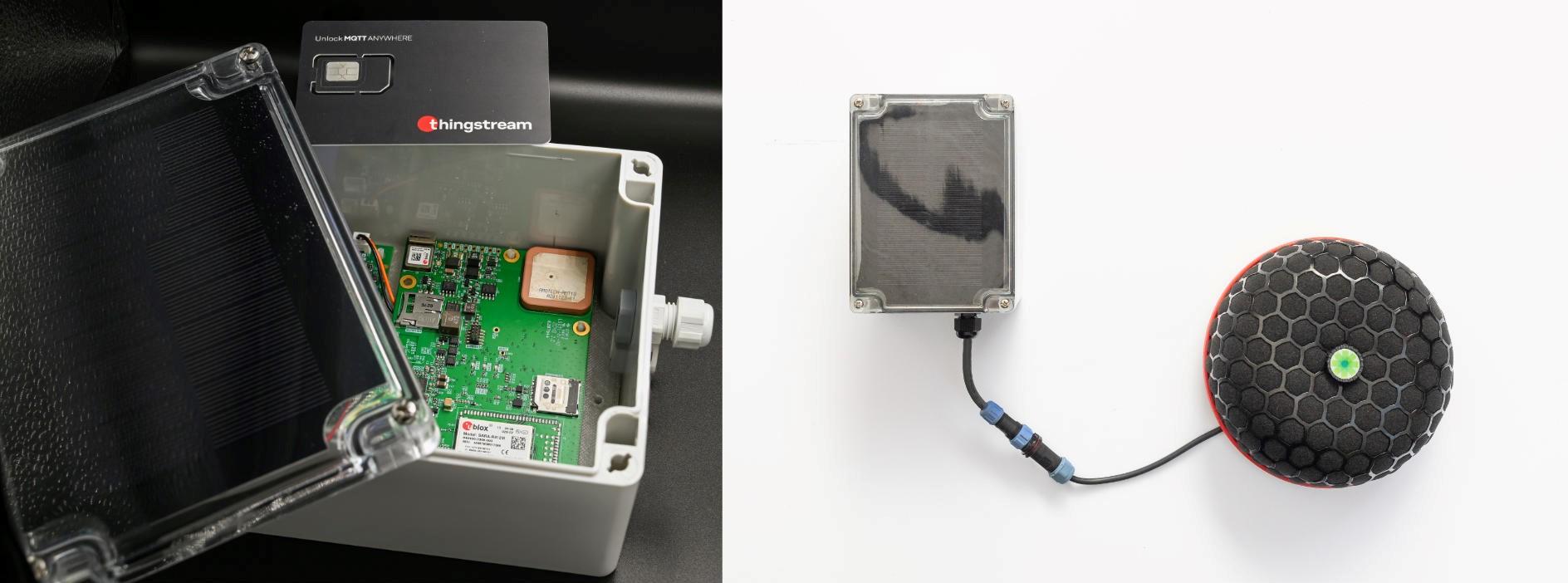

The Lattech Systems LS091 Power and Communication Module (PCM) is a weatherproof IoT/M2M edge product with an integrated solar panel. Harvested solar energy is stored and used to power both the connected sensors/actuators and communication to the cloud. Cloud connectivity is achieved via u-blox SARA-R412M LTE-M / NB-IoT / 2G cellular module and MQTT Anywhere SIM-based communication service and located by the EVA-M8 GNSS positioning module. The LS091 and Ping acoustic sensor are both attached at the base of each wind turbine via magnets locally by the customer in less than 1 minute.

A comprehensive end-to-end solution based on the industry-standard MQTT

Getting data from IoT devices anywhere in the world to the enterprise is simplified through MQTT Anywhere, the u-blox IoT communication service delivered via the Thingstream IoT cloud platform.

MQTT Anywhere offers:

- Access to 600+ cellular networks in 190 countries for global rollout of IoT devices

- MQTT-SN gateway enabling efficient connectionless LPWA communication

- Simple predictable pricing based on the number of MQTT messages

- Enterprise-grade IoT cloud platform utilizing auto-scaling technology

Once the Ping Monitor is attached to the customer’s wind turbine and is turned on, it automatically connects to the cloud and begins the important work of an intelligent listening sensor and of improving turbine performance through continuous monitoring in the cloud.

With Ping, "25% reduction in blade repair cost and 30% blade replacement can be avoided.2”

Early detection means earlier and more cost-effective repairs. Constant monitoring also removes the need to inspect towers that aren’t showing damage, which means you can reduce drone inspections to the pre-screened blades. Wind turbine operators can review data and analyze it remotely. User-defined notification criteria can be set so key stakeholders remain informed on any significant condition changes.

Blade replacement can cost in the range of 200,000 - 1,500,000 USD; whereas, damage repairs can cost, depending on severity, on the order of 4,000 - 50,000 USD. With a 25-30% reduction in both, it is easy to see the benefits adding up quickly.

With the expected global growth in electricity generated by wind energy, it is also easy to envision the immeasurable benefits to our planet and our future.

[citations]

1: https://www.energy.gov/eere/wind/how-do-wind-turbines-work

2: Wind Energy O&M Value Assessment for Ping Monitor Blade Acoustic Monitoring; Feng Zhang, Managing Consultant, Power and Renewables; Sep 2020

Featured products

<p>物联网通信即服务 SIM 基准站 LPWA</p>

SARA-R4 系列

LTE-M / NB-IoT / EGPRS 通信模块

EVA-M8 系列

具有成本效益的 u-blox M8 GNSS SiP

物联网 SIM 卡

让您的设备几乎可以在世界任何地方进行连接